Assembling 18650 lithium-ion battery pack operation Spot welding machine

technical details function and operation 1. Preparation before spot welding The

selection and trimming of the welding electrode head The size of the welding

electrode head and the distance between the two electrode heads have a great

influence on the welding quality. The thickness and material of the welding

workpiece have a great influence on the welding parameters. Welding of different

materials and structures should be selected according to the thickness and

material of the battery and battery sheet.

Function and operation 1. Preparation before spot welding Selection and

trimming of electrode head

The size of the welding electrode tip and the distance between the two

electrode tips have a great influence on the welding quality. The thickness and

material of the welding workpiece have a great influence on the welding

parameters. Welding electrode heads of different materials and structures should

be selected according to the thickness and material of batteries and battery

sheets. If the distance between the welding electrode heads is too large, the

welding cathode will increase, and the required energy will also increase

accordingly, and the weldment may not be firm. It is generally more appropriate

to adjust the distance between the two electrode heads to 3mm. Choose a welding

head with a suitable shape, and use a fine file or sandpaper to grind the

contact part to keep the welding head flat and smooth.

1) Turn on the power switch to check whether the equipment is operating

normally.

2) Check whether the spot welding surfaces of the two spot welding pins are

on the same horizontal plane, and check whether the spot welding surfaces of the

spot welding pins have been oxidized, burnt black or even mushroom-headed. The

welding pins are polished until the surface is smooth and oxide-free.

3) The spot welding machine is running normally, and the spot welding

needle has no oxidation and mushroom head-like phenomenon. Then, the current,

the height of the spot welding needle to the welding surface, and the air

pressure parameters are debugged for the spot welding machine. The debugging

effect is the result of spot welding. The product meets the following

requirements, otherwise it needs to be re-tested until the spot-welded product

can meet the requirements.

A: The solder joints of spot welded products have no phenomenon of fire or

burnt black.

B: The nickel sheet spot-welded on the positive electrode of the square

aluminum shell battery can withstand a pulling force of at least 3Kg on the

battery, the nickel sheet on the negative electrode can withstand a pulling

force of at least 1.5Kg on the battery, and the nickel sheet spot-welded on the

protective plate can withstand at least 1.5Kg of pulling force on the battery.

It can bear the pulling force of 1.5Kg.

C: The nickel sheet spot-welded on the positive electrode of the 18650

cylindrical battery can withstand a pulling force of at least 3Kg on the

battery, and the nickel sheet on the negative electrode can withstand a pulling

force of at least 3Kg on the battery.

4) After the battery spot welding machine is debugged and OK, the spot

welding operation shall be carried out after requesting. When spot welding the

positive pole of the aluminum shell battery, the nickel sheet connecting the

protective plate and the battery cell is placed on the composite aluminum-nickel

strip of the positive pole of the battery cell, and the spot welding machine is

started to perform spot welding twice in different places (the same spot cannot

be spot welded repeatedly 2 times), and at the same time ensure that there are 4

effective positive solder joints. When spot welding the negative electrode, put

the nickel strip on the negative electrode of the battery cell, start the spot

welding machine for spot welding, and there are only 2 effective welding spots

for the negative electrode.

4.2 When spot-welding 18650 cylindrical batteries with a battery spot

welding machine, put the nickel sheet at the positive and negative terminals of

the battery, and spot-weld twice at different places of the positive and

negative poles (the same spot cannot be spot-welded twice twice) to ensure

positive and negative poles at the same time. Each negative electrode has 4

effective solder joints.

4.3 When spot welding the protective plate, place the nickel sheet on the

nickel-plated steel sheet of the protective plate, start the spot welding

machine for spot welding, and at the same time ensure that there are 2 effective

welding spots.

5) During the spot welding operation, please do not adjust the height and

parameters of the spot welding machine and the weldment. However, if it is found

that the spot welding surfaces of the two welding pins are not on the same

level, the welding pins should be adjusted so that they are on the same level. )

Grind and maintain the spot welding needles with sandpaper and abrasive belt

every 1 hour (sandpaper should be parallel to the surface of the two welding

needles and polished to ensure that the spot welding surfaces of the two welding

needles are flat and at the same level , the abrasive belt should wrap the spot

welding needle for grinding) in order to remove the oxides that appeared on the

welding head of the spot welding needle in the previous operation, but within 1

hour, that is, before the next maintenance period, if the During the spot

welding operation, there is a phenomenon of explosion or blackening of the

solder joints or virtual welding or oxides on the spot welding needles. At this

time, the spot welding needles should be polished and maintained.

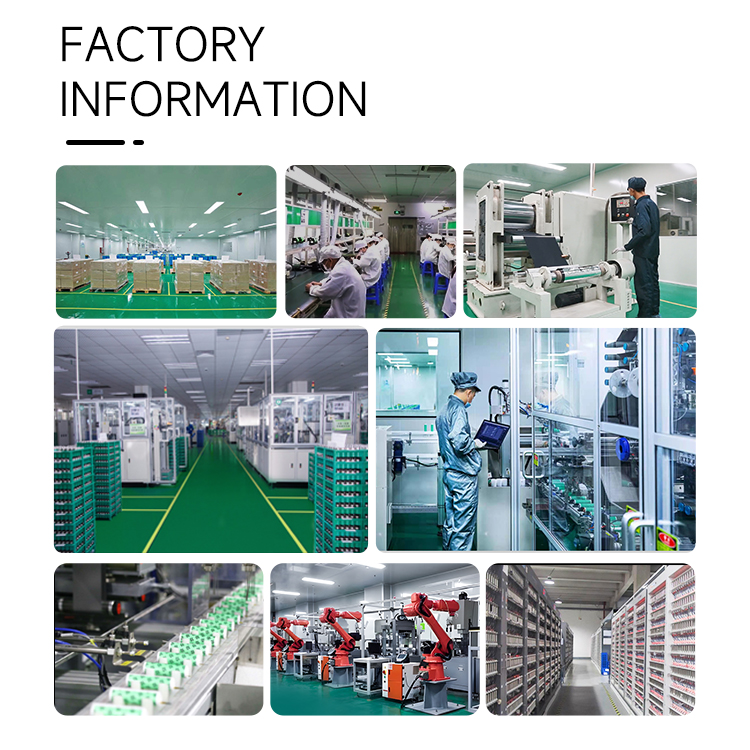

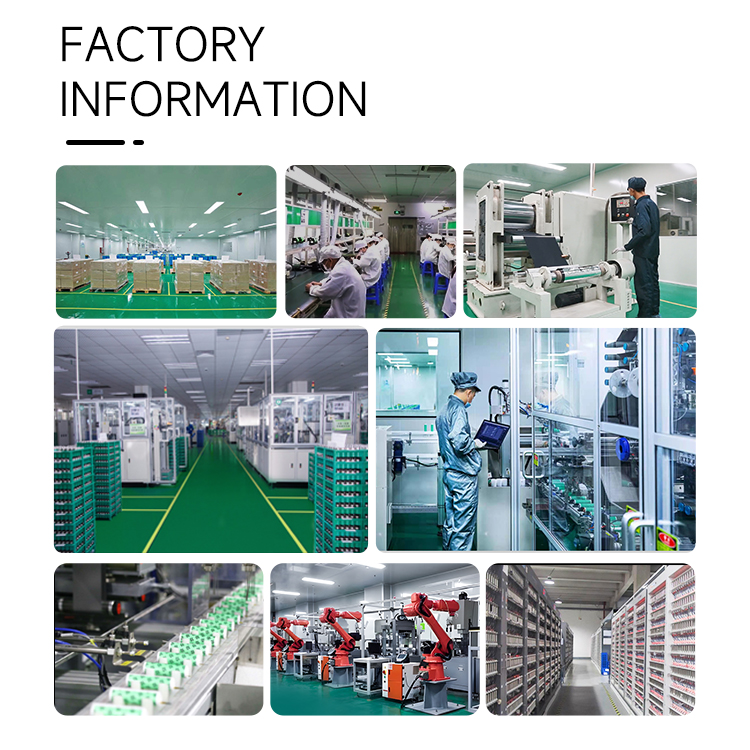

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP