High-speed CT technology restores the truth about thermal runaway of LG

18650 battery!

Once thermal runaway occurs in lithium-ion batteries, it will seriously

threaten the life and property safety of users. Therefore, how to prevent

thermal runaway is the ultimate goal of all lithium-ion battery designers.

However, in order to prevent the occurrence of thermal runaway from the design,

it is necessary to thoroughly understand the root causes of lithium-ion

batteries in the process of thermal runaway.

Once thermal runaway occurs in lithium-ion batteries, it will seriously

threaten the life and property safety of users. Therefore, how to prevent

thermal runaway is the ultimate goal of all lithium-ion battery designers.

However, in order to prevent thermal runaway from the design, it is necessary to

thoroughly understand the internal reaction process of the lithium-ion battery

during the thermal runaway process. However, the thermal runaway reaction speed

of lithium-ion batteries is fast, the temperature is high, and at the same time

limited by the sealed structure of lithium-ion batteries, it is difficult for us

to observe the reaction process of thermal runaway of lithium-ion batteries

intuitively and accurately.

X-rays have very strong penetrating ability and can pass through the shell

of lithium-ion batteries to observe the internal structure of lithium-ion

batteries. In particular, tomography technology allows us to directly generate

three-dimensional images of lithium-ion batteries, but usually X-ray imaging It

is relatively slow, and it is impossible to track the structural changes inside

the lithium-ion battery during the thermal runaway process of the lithium-ion

battery. The emergence of synchrotron radiation technology has greatly increased

the energy of X-rays, thereby effectively reducing the time required for

exposure, thus greatly improving the imaging speed. DonalP.Finegan (first

author) of London City College and others used synchrotron radiation technology

to greatly increase the speed of CT scanning, and conducted in-depth

understanding and research on the structural changes inside the 818650 battery

during the thermal runaway process.

In the experiment, DonalP.Finegan used two types of 18650 batteries from LG

as the research objects (with capacities of 2.2Ah and 2.6Ah respectively).

Through the application of the synchrotron radiation light source of the

European Synchrotron Radiation Center, DonalP.Finegan increased the adoption

speed of CT to 1.25Hz And 2.5Hz, while the ordinary two-dimensional shooting

speed reaches 1250Hz, which also allows us to "see" for the first time the

impact of thermal runaway gas production and high temperature on the structure

of lithium-ion batteries.

In the experiment, DonalP.Finegan used the high temperature method to

trigger thermal runaway of two LG 18650 batteries respectively (as shown in the

figure above). Among them, the core bone was added in the middle of the 2.6Ah

battery cell, which can serve as a support and is conducive to improving the

lithium-ion battery. The safety, while the 2.2Ah battery does not have a core

bone. The author used a thermal imager to track the temperature change of the

battery during the thermal runaway process (2.6Ah battery is video 1, 2.2Ah

battery is video 2). From the video, we can see that when the heating starts,

the temperature of the 2.6Ah battery shows a slow rising trend. At 168s, the

temperature of the battery casing rises to 230°C, and then the temperature of

the battery begins to rise rapidly to exceed 260°C (the temperature of the

thermal imager The highest observed temperature is 260°C), and then within a

very short period of time, due to the increase of gas pressure inside the

battery, the gas and electrode decomposition products inside the battery are

ejected from the position of the battery cover, and the battery thermal runaway

occurs. The thermal runaway time of the 2.2Ah battery was 217s after the heating

started.

In order to analyze the changes in the internal structure of LG batteries

during thermal runaway, DonalP.Finegan also used high-speed CT technology to

analyze the internal three-dimensional structures of 2.6Ah batteries (Video 3)

and 2.2Ah batteries (Video 4) during thermal runaway triggering. Scan and

rebuild. Because the 2.6Ah battery has a core bone inside the battery, it can

theoretically support the battery and prevent the battery from collapsing during

the thermal runaway process. The CT image of the 2.6Ah battery immediately

before the thermal runaway can It can be seen that the position of most of the

cells is still intact, but the cell structure is obviously deformed at the

center of the cell near the core bone, which may be caused by the separation of

positive and negative electrodes caused by local side reaction gas

production.

We can get the answer from the two pictures below about the stable use of

the core bone on the cell structure. In the picture a below, we can see that

because there is a core bone in the middle of the cell, the structure of the

cell does not occur after the battery is depressurized. Obvious damage, but in

Figure b below, we can see that the structure of the battery cell has been

significantly damaged after the battery pressure release occurs due to the

absence of the support of the core bone. This is mainly because a lot of gas has

accumulated between the positive and negative electrodes before the battery

pressure release occurs, so after the battery explosion-proof valve is opened,

the gas will be discharged along the position of least resistance, resulting in

no The supporting battery core has undergone significant deformation, and the

deformation of the battery core has also greatly increased the risk of short

circuit of the battery.

What voltage should be used to charge a 3.7v lithium battery

2018-06-01 81530 views

Generally, a 3.7v lithium battery needs a "protection board" for overcharge

and overdischarge. If the battery does not have a protection board, it can only

use a charging voltage of about 4.2v, because the ideal full charge voltage of a

lithium battery is 4.2v, and the voltage exceeds 4.2v. Damage to the battery,

while charging in this way, it is necessary to monitor the condition of the

battery at all times.

5v can be used if there is a protective board (4.8 to 5.2 can be used), the

USB5v of the computer or the 5v charger of the mobile phone can be used.

For a 3.7V battery, the charge cut-off voltage is 4.2V, and the discharge

cut-off voltage is 3.0V. Therefore, when the open circuit voltage of the battery

is lower than 3.6V, it should be able to charge. It is best to use the 4.2V

constant voltage charging mode, so you don't need to pay attention to the

charging time. Charging with 5V is prone to danger of overcharging.

1. Float charge. Refers to charging while working online. This method is

often used in backup power supply occasions. If it is lower than 12 volts, it

cannot be charged, and if it is too high, it will affect the operation of the

circuit. Therefore, when the floating charge works, the voltage is 13.8

volts.

2. Cycle charging. Refers to fully charging the battery to restore the

capacity. When fully charged, the charger is not disconnected for measurement.

Generally, it is around 14.5 volts, and the maximum does not exceed 14.9 volts.

After disconnecting the charger for 24 hours, it is generally around 13 volts to

13.5 volts. About 12.8 to 12.9 volts after a week. The specific voltage value of

different batteries is different.

The usual lithium battery cell is 3.7v, the voltage is 4.2v when fully

charged, the nominal voltage after series connection is only 7.4v, 11.1v,

14.8v... the corresponding full voltage (that is, the no-load output voltage of

the charger) is 8.4v, 12.6v, 16.8v... cannot be 12v integers, just like the

interval of lead-acid storage battery is 2v, full is 2.4v, correspondingly only

the nominal 6v, 12v, 24v... full voltage (The same is the output voltage of the

charger) respectively 7.2v, 14.4v, 28.8v... I don't know what kind of lithium

battery you are?

The output of the charger is generally 5V, and 4.9 volts is also a

non-standard. If you want to use this charger to charge the battery directly, it

will definitely not work, but as long as it is charged by a mobile phone or a

dock, it has a control circuit inside. It will be limited within the allowable

range of the lithium battery, unless the circuit is damaged, don't worry about

this

The usual lithium battery cell is 3.7v, the voltage is 4.2v when fully

charged, the nominal voltage after series connection is only 7.4v, 11.1v,

14.8v... the corresponding full voltage (that is, the no-load output voltage of

the charger) is 8.4v, 12.6v, 16.8v... cannot be 12v integers, just like the

interval of lead-acid storage battery is 2v, full is 2.4v, correspondingly only

the nominal 6v, 12v, 24v... full voltage (The same is the output voltage of the

charger) respectively 7.2v, 14.4v, 28.8v... I don't know what kind of lithium

battery you are?

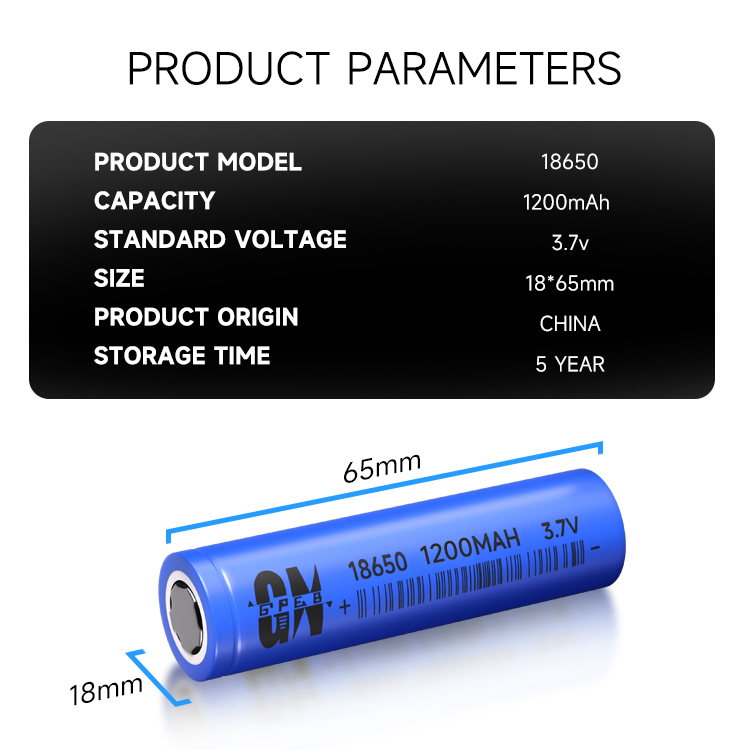

18500 batteries are widely used in cylindrical lithium batteries, and can

be used in electronic fields such as electronic cigarettes, toys, security, and

vehicles.

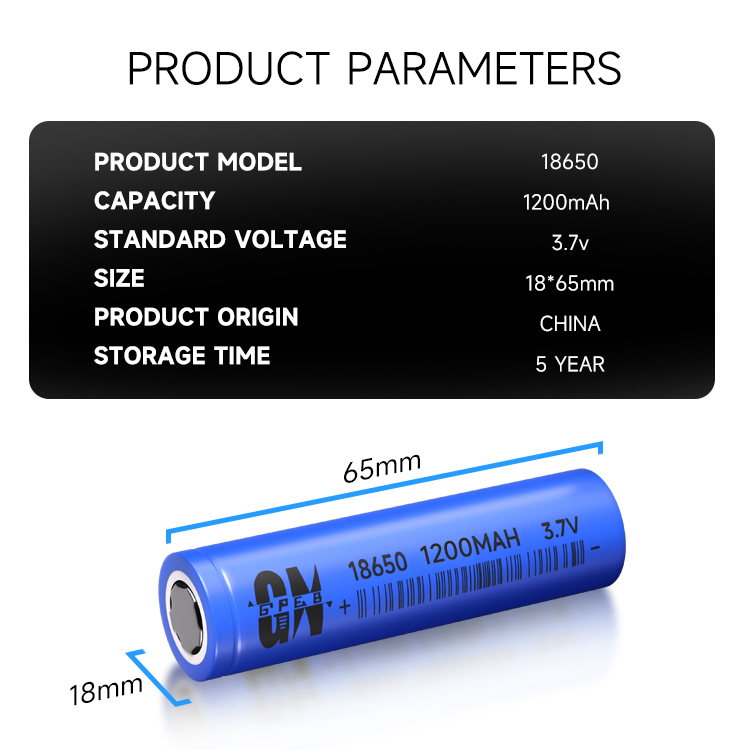

Enterprises with mature cell technology include BAK, Tiansheng, Huayuebao

and other manufacturers, with stable performance. The definition rule of its

model is: such as 18650 type, which refers to the battery with a diameter of

18mm and a length of 65mm, and a 18500 battery with a diameter of 18mm and a

length of 50mm, which is a cylindrical battery.

Voltage: 3.6V (conventional universal battery, used for electronic products

and low-power electrical equipment with a maximum discharge of 1C. Discharge

conditions can be changed according to the situation)

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP