Special Research on Ni-MH Battery Separator

Special research on Ni-MH battery separator (top-secret document), special

research on Ni-MH battery separator (top-secret document), type 1 of polyolefin

non-woven fabric, traditional wet-laid fiber composition: PP, PP/PE fiber size :

15-20 microns Features: Special research on the use of polyethylene and

poly-Ni-MH battery separators (top secret documents)

Types of Polyolefin Nonwovens

1. Composition of traditional wet-laid fibers: pp, pp/pE Fiber size: 15-20

microns Features: Use a mixture of polyethylene and polypropylene with high

uniformity, developed from the production of wet-laid paper, to meet The

combination of pp and pE, so a fiber with a relatively larger diameter should be

used.

2. Splicing fiber method Fiber composition: pp, pE+pEVOH Fiber size: 2-8

microns, 15-20 microns Features: It is also prepared by wet method, but the

difference is that the fibers are stitched and entangled using water flow.

Because of the problem of pinhole formation during the entangling process, the

basis weight minimum value of the product is limited to about 55 g/m2. When the

fineness diameter of the combined fiber is 2-8 microns, it is necessary to have

fibers with larger diameters to strengthen the strength of the product through

cross-linking. If the combination is not perfect, a uniform product will not be

obtained. Raw materials for the manufacture of such separators contain both

polyethylene fibers, polypropylene fibers and, in some cases, ethylene-vinyl

alcohol copolymer fibers.

3. Dry fiber composition: pure pp fiber size: 8-12 microns Features:

4. Melt-blown fiber composition: pure pp fiber size: 1-5 microns Features:

It is made of polypropylene by melt-blown method, usually does not contain

additives, so it will not reduce battery performance.

Surface treatment of polyolefin nonwovens Polyolefin nonwovens are

generally hydrophobic and require surface treatment to make them hygroscopic

before being used as separators for alkaline batteries. The most common methods

are:

1. Treatment with surfactant is to make it hydrophilic by coating with

anionic or nonionic surfactant. The main disadvantage of this method is that the

surfactant will quickly dissipate from the separator, which will pollute the

electrolyte and electrodes of the battery. As a result, the separator will

become hydrophobic, and the intervention of impurities will cause a decrease in

battery performance.

2. Corona discharge is a method of subjecting the diaphragm to high-voltage

discharge to oxidize the surface of the polymer to make it hydrophilic. The time

of this treatment should not be too long, and the water absorption of the

diaphragm will be lost after a long time of use.

3. Fluorine gas treatment is to treat the diaphragm with fluorine gas

diluted in an inert gas such as nitrogen or argon, and another reactive gas such

as sulfur dioxide is also added to the mixed gas. The diaphragm treated by this

method has a certain degree of hydrophilicity, and this method has the least

effect on the tensile strength of the diaphragm.

4. Adding hydrophilic fibers By adding a relatively small portion of

hydrophilic fibers, the polyolefin nonwoven separator can have water immersion.

A commonly used fiber is ethylene-vinyl alcohol copolymer (pEVOH).

5. Sulfonation treatment This process includes the hydrophilic treatment of

the surface of the non-woven fabric in sulfuric acid or similar chemical

solvents. This process exposes sulfuric acid to the fiber surface, but this also

causes degradation of the polyolefin due to chemical oxidation reactions. As a

result of the treatment, the tensile properties of the nonwoven are reduced.

Because of degradation due to oxidation reactions, only polyethylene-covered

polypropylene fibers can be used, such that fiber diameters are limited to 15

microns or larger. Fine pure polypropylene fibers cannot be treated in this

way.

6. Graft copolymerization of vinyl is the most commonly used method among

the above processes. All types of nonwoven separators are treated for effective

and long-lasting water immersion. Grafting acrylic on vinyl is the most

effective method, usually using radiation techniques. The radiation grafting

process can produce a uniform and hydrophilic separator, and at the same time,

it can improve the mechanical properties of the non-woven separator. Another

advantage of the process is to add ion-exchange properties to the separator,

thereby improving battery performance, such as charge retention and cycle time

after charge.

Diaphragm performance

1, Mechanical properties Tensile strength is a very important parameter, it

varies with the structure of the diaphragm, the type of fiber, the diameter of

the fiber and the quantitative of the diaphragm. Surface treatment can also

affect the mechanical properties of the separator.

① Melt blown method - graft weight (g/m2): 50 Tensile strength MD (N/m):

1200 Elongation (%): 20

②Dry method-grafting weight (g/m2): 58 Tensile strength MD (N/m): 3500

Elongation (%): 20

③Wet method - graft weight (g/m2): 58 Tensile strength MD (N/m): 3500

Elongation (%): 20

④ Wet method - sulfonation quantitative (g/m2): 62 Tensile strength MD

(N/m): 2100 Elongation (%): 11

⑤ Split fiber method - fluorine treatment Quantitative (g/m2): 60 Tensile

strength MD (N/m): 3700 Elongation (%): 25

⑥ Adding hydrophilic fiber quantitative (g/m2): 57 Tensile strength MD

(N/m): 2000 Elongation (%): 20

A separator with a tensile strength above 3000N/m has no problem in rolling

batteries. If the tensile strength is less than 2000N/m, care must be taken when

winding the battery to avoid damage to the separator and short circuit of the

battery. The separator produced by the melt blown method can only be used for

square batteries, because the tension of the separator during the battery

production process is not serious. A particular benefit of using radiation

grafting is the increased tensile strength of the separator. ②Chemical stability

In order to prolong battery life and operate reliably, the separator must have

high chemical stability inside the battery. The figure below shows the

relationship between the time and the tensile strength of the three grafted

membranes immersed in 30% KOH solution at a temperature of 70°C. For comparison

the effect of immersion on typical nylon diaphragms is listed in this figure.

These results represent the degradation characteristics of nylon, while clearly

showing the long-term stability of polyolefin materials. In addition, the table

below shows that the tensile properties of polyolefin non-woven separators will

not be affected even after hundreds of charge and discharge cycles. ③ The rapid

floodability of the water-immersible separator in the electrolyte can ensure

rapid and effective battery production. The following table shows the typical

absorption rate for the optimal removal of liquid in the separator of Ni-MH

battery. These data clearly show that all the grafted nonwoven separators have

better water soakability and wetting speed. And the non-woven membrane made by

the melt-blown method with fine fiber and small pore size has the highest

wetting speed. The separators are only suitable for prismatic batteries, which

are being developed for use in electric vehicles, only after they have been

treated by radiation grafting. To guarantee stable battery performance during

cycling, the water immersion of the separator must not be affected during the

working life of the battery. However, the corona discharge and fluorination

treatment of the surface of the non-woven separator will degrade its water

immersion performance with time. But radiation grafting is a permanent treatment

for polyolefin materials, and they remain water-immersive all the time. The

figure below shows the wetting speed as a function of time for two grafted

polypropylene nonwoven separators and one fluorine-treated nonwoven separator in

KOH at 70°C. The results showed that the grafted nonwoven membrane was the best

at maintaining immersion.

④ Absorption and retention of electrolyte The ability of the separator to

absorb and retain electrolyte is an important parameter for battery performance.

For ideal battery performance, the separator must have a high and uniform

absorption rate of the electrolyte. Further, to ensure long cycle life, the

separator must be able to hold enough electrolyte to prevent the separator from

drying out during cycling. The table below presents data quantifying electrolyte

absorption and retention for a separator of approximately 60 g/m2. The

electrolyte holding capacity was measured by the amount of electrolyte squeezed

out after the separator was pressurized. In order to maximize the cycle life of

the battery, the electrolyte should be retained as much as possible. 1.

Electrolytic meltblown method-absorption and retention of grafted electrolyte:

300 (g/m2) electrolyte retention: 19.7 (g/m2) electrolyte retention rate (%):

6.6

2. Dry method - absorption and retention of grafted electrolyte: 190 (g/m2)

electrolyte retention: 14.8 (g/m2) electrolyte retention rate (%): 7.8

3. Absorption and retention of wet method-grafted electrolyte: 160 (g/m2)

Electrolyte retention: 9.3 (g/m2) Electrolyte retention (%): 5.8

4. Absorption and retention of wet-sulfonated electrolyte: 140 (g/m2)

Electrolyte retention: 8.8 (g/m2) Electrolyte retention (%): 5.7

5. Spliced fiber method - absorption and retention of grafted electrolyte:

180 (g/m2) electrolyte retention: 13.7 (g/m2) electrolyte retention (%): 7.6

6. Combined fiber method - fluorine treatment Electrolyte absorption and

retention: 230 (g/m2) Electrolyte retention: 12.6 (g/m2) Electrolyte retention

(%): 5.5

7. Combined fiber method plus hydrophilic fiber absorption and retention of

electrolyte: 210 (g/m2) electrolyte retention: 14.3 (g/m2) electrolyte retention

rate (%): 6.8 The main influence on the retention capacity of electrolyte is the

diameter of the fiber, and the diameter of the fiber is also a factor

controlling the pore size of the diaphragm. For prismatic batteries, non-woven

separators made by meltblown method are the best choice, while for sealed roll

batteries, dry-laid non-woven separators are the best choice.

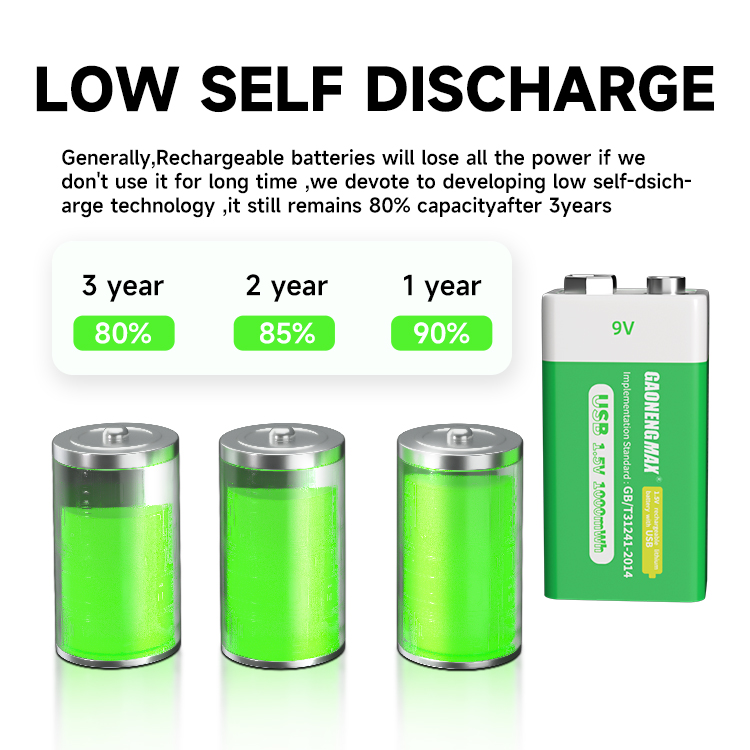

⑤ Impurity Separation/Self-discharge Performance Ni-MH batteries have

relatively large self-discharge. However, the self-discharge rate of Ni-MH

batteries using grafted and sulfonated polyolefin non-woven separators can reach

the level of Ni-Cd batteries. One reason for this performance improvement is

that the chemical stability of the polyolefin nonwoven separator is strong,

which can prevent the pollution of the battery, and the impurity is the cause of

the accelerated self-discharge. For example, the nylon separator will accelerate

the self-discharge of the battery due to the intervention of nitrogen in the

impurity. In addition, a very important feature of the radiation-grafted

polyolefin non-woven separator is to effectively reduce the content of

impurities that cause accelerated self-discharge. The ion-exchange properties of

these membranes have been documented to absorb and block impurities such as

metal ions and ammonia. These pollutions will cause corrosion of the electrodes

in the battery, just like impurities inside the electrodes. For example, nitrate

impurities in the positive electrode may decrease to become ammonia in the

negative electrode, thereby accelerating self-discharge. This is the so-called

nitrogen conduction reaction. Ammonia absorption capacity of grafted membrane:

1, wet method - absorption capacity of grafted ammonia (NH3mmol/g): 3.0

2. Combined fiber method - grafted ammonia absorption capacity (NH3mmol/g):

3.6

3. Absorption capacity of dry-grafted ammonia (NH3mmol/g): 4.0

4. Melt-blown method-absorption capacity of grafted ammonia (NH3mmol/g):

5.2

5. Meltblown method - Absorption capacity of ammonia without grafting

(NH3mmol/g): 0

Charge retention capacity of Ni-MH battery after storage for 7 days at

70°C: 1, charge rate of grafted pp (%): 80

2, Fluorine treatment charging rate (%): 54

3, Coronadischargepp charging rate (%): 50

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP