Protection board scheme for series lithium battery balanced charging

battery pack

Electronic enthusiasts provide you with a protection board solution for

series lithium battery balanced charging battery packs. This article is aimed at

the use of power lithium batteries in groups. Each lithium battery requires

protection from charging overvoltage, discharging undervoltage, overcurrent, and

short circuit. In order to achieve the problem of balanced charging of the whole

group of batteries, a single-cell lithium battery protection chip is designed to

protect any string

When a group of lithium batteries are charged in series, each battery

should be charged in a balanced manner, otherwise the performance and life of

the whole group of batteries will be affected during use. Commonly used balanced

charging technologies include constant shunt resistor balanced charging, on-off

shunt resistor balanced charging, average battery voltage balanced charging,

switched capacitor balanced charging, step-down converter balanced charging,

inductive balanced charging, etc. However, the existing single-cell lithium

battery protection chip does not contain the balanced charging control function;

the balanced charging control function of the multi-cell lithium battery

protection chip requires an external CpU, which is realized through serial

communication (such as I2C bus) with the protection chip, increasing It

increases the complexity and design difficulty of the protection circuit,

reduces the efficiency and reliability of the system, and increases the power

consumption.

This paper aims at the use of power lithium batteries in groups. Each

lithium battery requires the protection of charging overvoltage, discharging

undervoltage, overcurrent, and short circuit. The protection chip is a battery

pack protection board with a balanced charging function that protects any number

of lithium batteries in series. The simulation results and industrial production

application prove that the protection board has perfect protection function,

stable operation, high cost performance, and the equalization charging error is

less than 50mV.

Lithium battery pack protection board equalization charging basic working

principle

A schematic diagram of a lithium battery pack protection board with

balanced charging capability designed using a single-cell lithium battery

protection chip is shown in Figure 1. Among them: 1 is a single-cell lithium-ion

battery; 2 is the resistance of the charge overvoltage shunt discharge branch; 3

is the switching device for shunt discharge branch control; 4 is the overcurrent

detection protection resistor; 5 is the omitted lithium battery protection chip

and circuit Connection part; 6 is a single-cell lithium battery protection chip

(generally including charge control pin CO, discharge control pin DO, discharge

overcurrent and short circuit detection pin VM, battery positive terminal VDD,

battery negative terminal VSS, etc.); 7 is The charging overvoltage protection

signal is isolated by the optocoupler and forms a parallel relationship to drive

the gate of the MOS tube for charging control in the main circuit; 8 is the

discharge undervoltage, overcurrent, and short circuit protection signal, which

is isolated by the optocoupler and forms a series relationship to drive the

discharge in the main circuit MOS tube grid for control; 9 is a charge control

switch device; 10 is a discharge control switch device; 11 is a control circuit;

12 is a main circuit; 13 is a shunt discharge branch. The number of single-cell

lithium battery protection chips is determined according to the number of

lithium battery cells, and they are used in series to protect the charging and

discharging, over-current, and short-circuit states of the corresponding

single-cell lithium battery. At the same time of charging protection, the system

realizes balanced charging through the protection chip to control the on-off of

the switch device of the shunt discharge branch. The cost of the

application.

When the lithium battery pack is charging, the positive and negative poles

of the external power supply are respectively connected to the positive and

negative poles BAT+ and BAT- of the battery pack, and the charging current flows

through the positive pole BAT+ of the battery pack, the single-cell lithium

batteries 1~N in the battery pack, and the discharge control switch device. ,

the charge control switch device, the negative electrode BAT- of the battery

pack, and the current flow direction is shown in FIG. 2 .

The charging overvoltage protection control signal of the single-cell

lithium battery protection chip in the control circuit part of the system is

isolated by the optocoupler and output in parallel to provide the gate voltage

for the conduction of the charging switch device in the main circuit; such as a

certain lithium battery or several lithium batteries In the process of charging,

it first enters the overvoltage protection state, then the overvoltage

protection signal controls the discharge of the shunt discharge branch connected

in parallel to the positive and negative terminals of the single lithium

battery, and at the same time disconnects the corresponding single lithium

battery connected in series in the charging circuit. out of the charging

circuit.

When lithium battery packs are charged in series, the influence of the

capacity difference of single cells is ignored, and the battery with smaller

internal resistance is generally charged first. At this time, the corresponding

overvoltage protection signal controls the switching device of the shunt

discharge branch to close, and a shunt resistor is connected in parallel at both

ends of the original battery. According to the pNGV equivalent circuit model of

the battery, the shunt branch resistance at this time is equivalent to the load

of the single-cell lithium battery that is fully charged first, and the battery

is discharged through it to maintain the battery terminal voltage within a very

small range near the full state. Assuming that the first lithium battery is

charged first and enters the overvoltage protection state, the current flow in

the main circuit and the shunt discharge branch is shown in Figure 3. When all

single-cell batteries are charged and enter the over-voltage protection state,

the voltages of all single-cell lithium batteries are completely equal within

the error range, and the charging protection control signals of each protection

chip become low, and the charging control switching device in the main circuit

cannot be used. Provide grid bias to turn it off and disconnect the main

circuit, that is to achieve balanced charging, and the charging process is

completed.

When the battery pack is discharged, the external load is connected to the

positive and negative poles BAT+ and BAT- of the battery pack respectively, and

the discharge current flows through the negative pole BAT- of the battery pack,

the charge control switch device, the discharge control switch device, and the

single-cell lithium battery N in the battery pack. ~1 and the positive pole BAT+

of the battery pack, the current flow direction is shown in Figure 4. The

discharge undervoltage protection, overcurrent and short circuit protection

control signals of the single-cell lithium battery protection chip in the

control circuit of the system are output in series after being isolated by the

optocoupler, and provide the gate voltage for the conduction of the discharge

switch device in the main circuit; once the battery pack In the process of

discharging, if a single-cell lithium battery encounters special conditions such

as undervoltage, overcurrent, and short circuit, the corresponding single-cell

lithium battery discharge protection control signal becomes low, and the gate

bias cannot be provided for the discharge control switching device in the main

circuit. Turn it off and disconnect the main circuit, that is, end the discharge

and use process.

Generally, lithium batteries adopt constant current-constant voltage

(TApER) charging control. When charging at constant voltage, the charging

current decreases approximately exponentially. The switching device of the

charging and discharging main circuit in the system can be selected according to

the maximum operating current and operating voltage required by the external

circuit.

The single-cell lithium battery protection chip of the control circuit can

be selected according to the voltage level and protection delay time of the

single-cell lithium battery to be protected.

The resistance of the discharge branch connected to both ends of a single

battery can be calculated according to the charging voltage of the lithium

battery charger, the parameters of the lithium battery and the discharge

current. The equalization current should be selected reasonably. If it is too

small, the equalization effect will not be obvious; if it is too large, the

energy loss of the system will be large, the equalization efficiency will be

low, and the thermal management requirements for lithium battery packs are high.

Generally, the current can be designed between 50 and 100mA.

The resistance of the shunt discharge branch can be realized by using a

power resistor or a resistor network. Here, it is more reasonable to use a

resistor network to realize the resistance of the shunt discharge branch, which

can effectively eliminate the influence of resistance deviation, and in

addition, it can also play a role in reducing thermal power consumption.

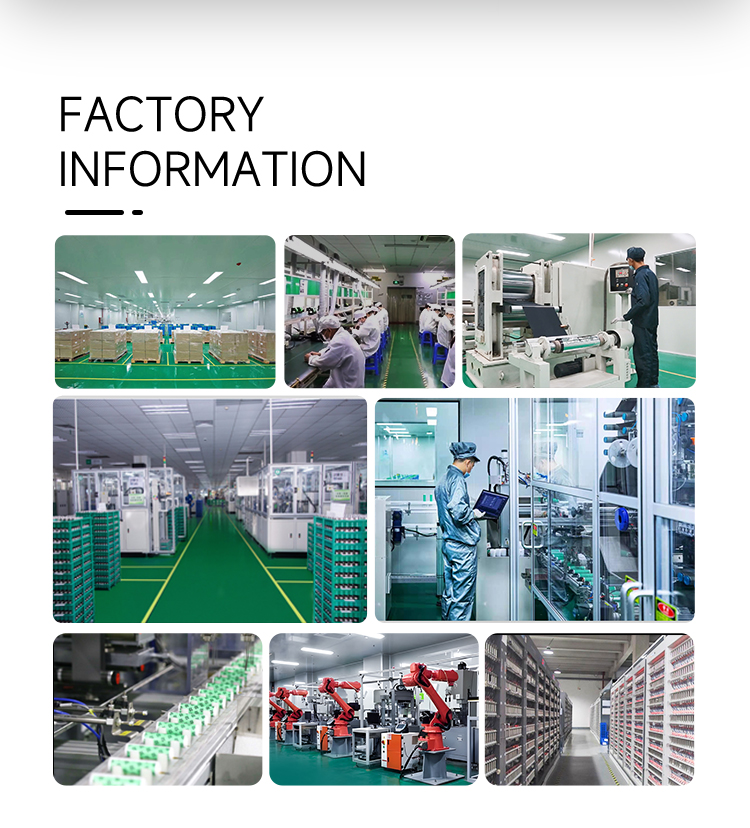

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP