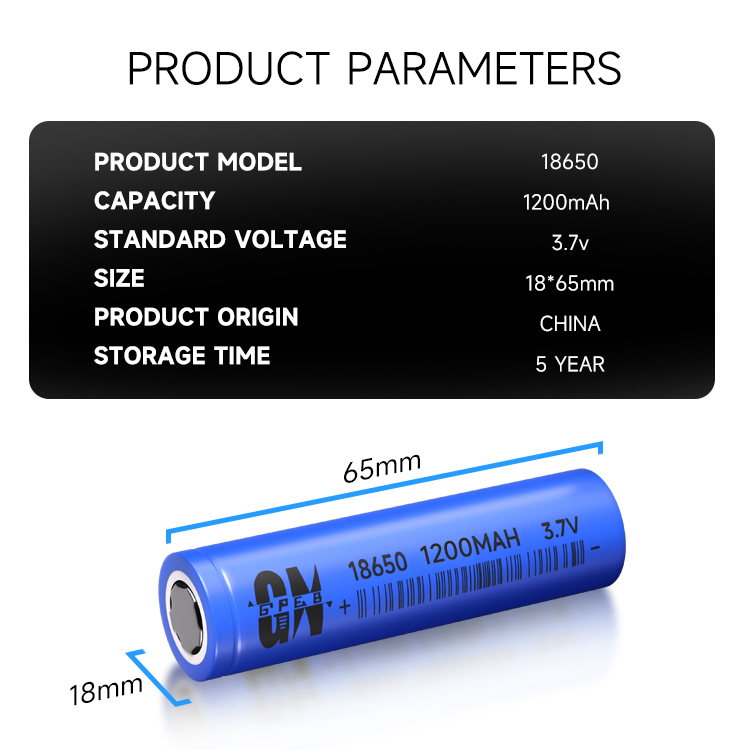

18650 lithium-ion battery winding step process should pay attention to the

problem

Battery Information 18650 Lithium battery winding step process to pay

attention to 1. Humidity control ≤ 1%RH Purpose: To prevent positive and

negative electrode sheets from absorbing water during the winding process,

resulting in zero voltage, self-discharge, and poor cycle performance; method:

Calculate the dew point value and temperature value to get the temperature and

humidity value; 2. Dust control ≤100,00

18650 lithium-ion battery winding step process should pay attention to the

problem

1. Humidity control ≤1%RH Purpose: To prevent positive and negative

electrode sheets from absorbing water during the winding process, resulting in

zero voltage, self-discharge, and poor cycle performance;

Method: Calculate the dew point value and temperature value to obtain the

temperature and humidity value;

2. Dust control ≤100,000pc/ft3 (detection particle size is 0.5um)

Low temperature lithium iron phosphate battery 3.2V 20A -20℃ charge, -40℃

3C discharge capacity ≥70%

Charging temperature: -20~45℃ -Discharging temperature: -40~+55℃ -40℃

supports maximum discharge rate: 3C -40℃ 3C discharge capacity retention

rate≥70%

Click for details

Purpose: To prevent dust from being involved in the electrode group during

winding, causing short circuit, overheating, fire, self-discharge and other

defects in the battery cell;

Method: use a dust tester;

3. Abnormal cutting burrs

Process requirements: pole piece ≤ 8um; tab burr ≤ 12um; detection method:

randomly select 1PCS cell for dissection in the first inspection of each machine

in each shift, and detect the front and rear ends of the positive and negative

electrodes and the positive and negative electrodes according to the "burr

detection operation guide" Ear clipping burrs.

Adverse effects: The burrs on the pole pieces or tabs exceed the process

requirements, which may cause the burrs to pierce the diaphragm, short-circuit

the positive and negative electrodes, overheat the battery cells, and may

explode in severe cases, posing serious safety hazards.

Low temperature high energy density 18650 3350mAh-40℃ 0.5C discharge

capacity ≥60%

Charging temperature: 0~45℃ Discharging temperature: -40~+55℃ Specific

energy: 240Wh/kg -40℃ discharge capacity retention rate: 0.5C discharge

capacity≥60%

Click for details

4. Poor coverage of positive and negative electrodes

Process requirements: the alignment of positive and negative plates is

0.75~.55mm

Negative plate and diaphragm alignment 1?.5mm

Detection method: continuous random inspection of 3PCS cells after reel

change, detection of alignment according to the "X-RAY Operation Instructions"

Adverse effects: 1) The alignment of positive and negative electrodes exceeds

the process specification, which may cause the negative electrode to not cover

the positive electrode During the charging process, the lithium ions released

from the positive electrode cannot find the corresponding graphite to embed,

resulting in free lithium ions in the battery cell accumulating on the negative

electrode and forming dendrites. The dendrites penetrate the separator and cause

an internal short circuit, which poses a safety hazard.

2) If the alignment between the negative electrode and the diaphragm

exceeds the process standard, the negative electrode may be squeezed and

deformed, and the negative material on the electrode may fall off. During the

charging process, the battery cell expands, and the powder penetrates the

diaphragm, causing the internal short circuit of the positive and negative

electrodes to cause safety. Hidden danger;

5. Poor coverage of the pole piece in the winding direction (the length of

the outer layer negative electrode exceeds the length of the positive electrode

material, and the length of the inner layer negative electrode exceeds the

length of the positive electrode material) detection method: every 2H each

winding machine randomly checks the dissection of 3PCS batteries, and measures

the two parts with eyepieces and rulers respectively. A coverage gap size.

Adverse effects: It may cause the negative electrode sheet not to enclose

the positive electrode sheet. During the charging process of the battery, the

lithium ions released from the positive electrode cannot find the corresponding

graphite to embed, causing free lithium ions in the battery cell to accumulate

on the negative electrode and appear dendrites. Dendrites puncture the separator

and cause internal short circuit, which poses a safety hazard.

6. Short circuit test

Parameter setting (100V, 25nF250V,

250uA) Detection method: test the machine with a short-circuit sample

during the first inspection of each shift; adverse effects: self-discharge,

heat, explosion and other short-circuit factors: cutting particles, metal dust,

burrs, etc. cause diaphragm holes;

7. Tab sticking foil and tension

Process requirements: tensile force ≥ 15N sticky foil area 2/3 welding

printing

Detection method: Sampling 1PCS cell every 2H, dissecting, measuring

tension, checking foil sticking

Bad effect: high internal resistance

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP