Mechanism of Axial Pressure Leading to Failure of 18650 Cylindrical Li-ion

Batteries

With the rapid development of the electric vehicle industry, lithium-ion

batteries are widely used in the field of power batteries due to their

advantages such as high energy density, no memory effect and high safety.

With the rapid development of the electric vehicle industry, lithium-ion

batteries are widely used in the field of power lithium batteries due to their

advantages such as high energy density, no memory effect and high safety. Due to

the particularity of electric vehicles, higher requirements are placed on the

safety of power lithium batteries. For example, in the event of a safety

accident such as a collision of an electric vehicle, the power lithium battery

must not catch fire or explode to ensure the safety of drivers and passengers.

Therefore, the power lithium battery safety test includes extrusion, acupuncture

and other tests related to the safety performance of lithium-ion batteries under

extreme abuse. Whether it can pass these rigorous safety tests is the key to

evaluating a lithium-ion battery. The ultimate standard in battery safety.

In the extrusion test, the shell of the lithium-ion battery first deforms,

and then begins to squeeze the cell. Due to the low strength of the separator

prepared by the current dry stretching process in the transverse and diagonal

directions, it is difficult for the cell to When the deformation reaches a

certain level, the transverse direction of the diaphragm will break first,

resulting in direct contact between the positive and negative electrodes of the

lithium-ion battery, a short circuit occurs, and a large amount of heat is

released instantaneously, resulting in the decomposition of the negative

electrode SEI film, positive electrode active material and electrolyte. This

leads to thermal runaway of the Li-ion battery, which eventually causes the

Li-ion battery to catch fire and explode.

In order to prevent the thermal runaway of lithium-ion batteries in the

extrusion test and improve the safety of lithium-ion batteries, it is necessary

to conduct in-depth research on the mechanism of thermal runaway of lithium-ion

batteries in the extrusion test, so as to carry out research on lithium-ion

batteries. Targeted safety design to improve the safety of lithium-ion batteries

in extrusion tests. Let's take a look at the relevant research results of the

Massachusetts Institute of Technology.

JunerZhu et al. from the Massachusetts Institute of Technology used 18650

batteries to study the mechanism of thermal runaway of lithium-ion batteries in

the process of axial extrusion, and performed simulation analysis using the

finite element analysis model, which restored different The impact of axial

pressure on lithium-ion batteries, the analysis results were verified by CT

scans, and the simulation analysis results found two reasons that could explain

the short-circuit of lithium-ion batteries in the extrusion test.

Since the 18650 battery in the power lithium battery pack is generally

assembled vertically, when the battery pack is dropped, the axial extrusion is

an important reason for the deformation of the lithium-ion battery. Therefore,

JunerZhu mainly studied the battery under axial pressure Mechanism of

deformation-induced short-circuiting in Li-ion batteries. Some traditional

models assume that the inside of the lithium-ion battery is a uniform whole, so

they cannot accurately predict the test results when predicting the axial

compression test of the 18650 battery. This is mainly due to the special

structure of the lithium-ion battery cell, which leads to The upper and lower

parts of the core are not exactly the same. At the same time, due to the unique

structure of the lithium-ion battery cover (that is, the positive electrode),

when the lithium-ion battery is subjected to axial pressure, it may cause the

lithium-ion battery to fail before the internal short circuit occurs. A short

circuit has occurred.

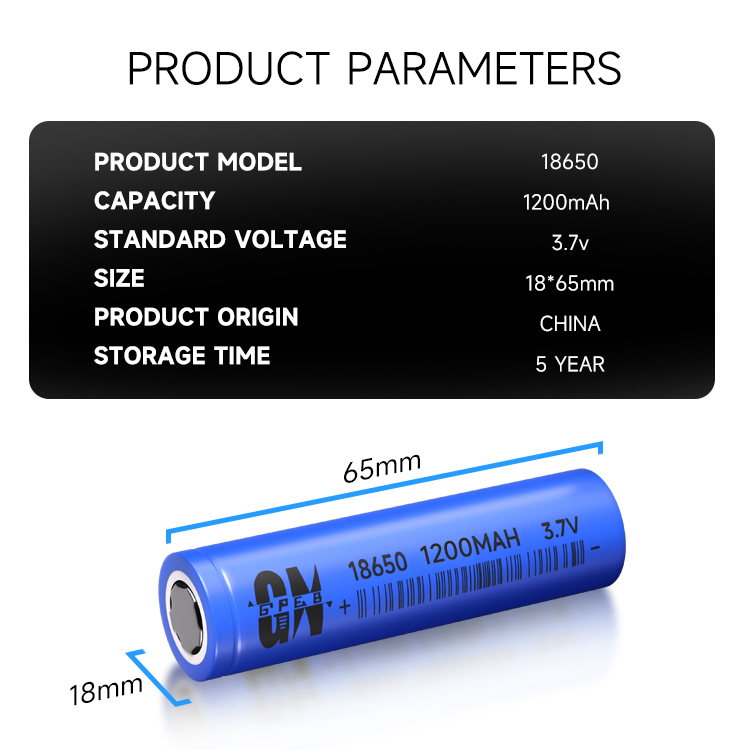

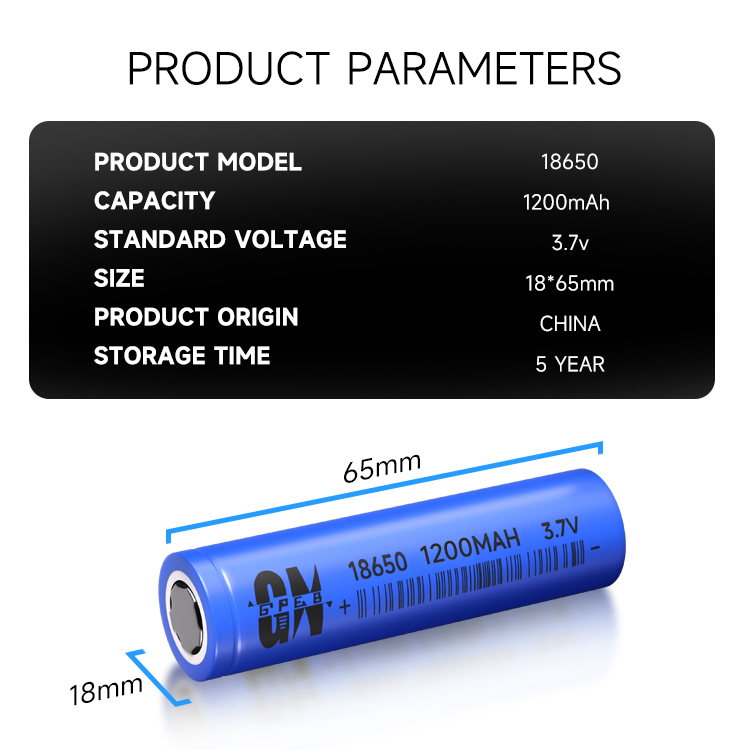

The 18650 battery is mainly composed of three parts: a safety valve, a

winding core and a mild steel case. The safety valve is usually composed of

positive temperature coefficient material, aluminum safety valve, stainless

steel positive terminal, gas sealing gasket, etc. The battery cell is composed

of positive electrode, negative electrode and diaphragm. In this test, the

active material of the positive electrode is LiCoO2. The loading speed of the

axial load was 5mm/min, and all the test cells had been fully discharged (SOC=0)

before the test. The test results show that the pressure of the 18650 battery in

the axial pressure test shows a trend of slow rise, rapid rise, slight decline,

and rapid rise. The voltage test shows that the 18650 battery will not fail

until the deformation reaches 4mm, and it is found through the test that, The

voltage drop of the 18650 battery is mainly caused by the internal short circuit

of the battery, not the open circuit of the internal structure. In order to

study the failure mechanism of 18650 under axial pressure, JunerZhu also used

finite element software to analyze it. The material in the model mainly adopts

the elastoplastic model, and considers the anisotropy characteristics of various

materials. In the model Contains millions of computing units, and the loading

speed of the axial load is set to 1m/s.

The simulation results reproduce the deformation process of the 18650

battery under the axial load. First of all, the casing in the upper cover area

of the battery begins to undergo plastic deformation. After the deformation

exceeds 1mm, the deformed casing begins to squeeze the upper part of the battery

core. With the increase in the deformation, the battery core begins to deform.

There is a slight drop on the curve, and then as the contact area between the

battery case and the battery cell increases, the pressure curve presents a rapid

upward trend. The CT scanning results also verified the above analysis well. The

deformation of the test battery mainly occurred in the upper structure, and the

lower battery hardly deformed.

The dismantling of the 18650 battery after the test showed that although

the battery core was severely deformed, the positive and negative electrodes did

not break, but a crack appeared in the diaphragm at a distance of 1.3 mm from

the upper edge, which directly caused the battery to break. There was a short

circuit, a sudden drop in voltage, and this crack was probably caused by the

intrusion of the sharp edge of the metal foil. In addition, the thickness of the

diaphragm has dropped greatly in some places, which is mainly due to the

extrusion of the battery core by the concave shell.

From the above analysis results, the possible reasons for the short circuit

of the 18650 battery under axial pressure are as follows.

1. The casing is in contact with the positive and negative electrodes

through the ruptured diaphragm

2. The positive and negative electrodes are in contact through the ruptured

separator

3. The positive and negative electrodes contact through the thinned area of

the separator

4. The safety valve is squeezed and comes into contact with the cell

360° FACTORY VR TOUR

360° FACTORY VR TOUR

Whatsapp

Whatsapp

Tel

Tel Email

Email TOP

TOP